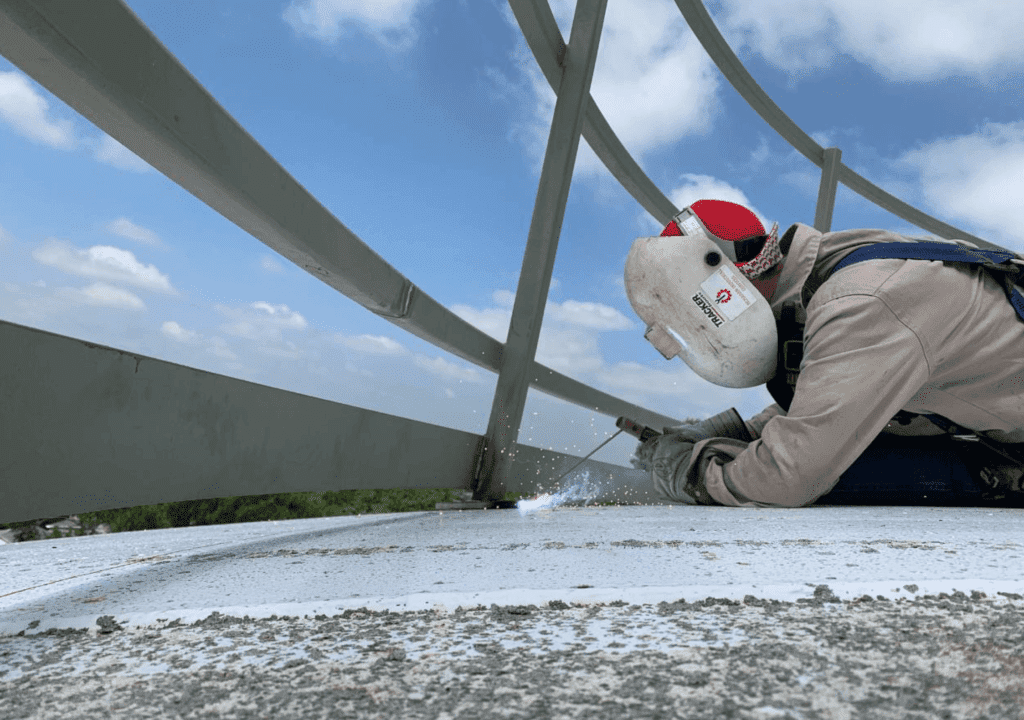

Wind turbine maintenance in Kansas City, MO, relies heavily on aerial welding, a crucial process used by McMahan Industrial Services.

Here, they repair and maintain the structural integrity of massive turbine blades. These blades are prone to cracks, erosion, and damage from extreme weather conditions, making regular maintenance essential to prevent costly replacements and guarantee peak performance.

At McMahan Industrial Services, our aerial welding techniques are specifically designed to restore cracks and damage, particularly in leading edges, which are vulnerable to erosion and cracking.

Our expert team uses cutting-edge technologies and strategies to drive this field forward, ensuring that your turbines are always running at their best.

Turbine Blades Need Repair

Wind turbine blades, massive structures that can reach up to 80 meters in length, are prone to cracks, erosion, and other forms of damage. This damage can compromise their structural integrity and overall functionality.

At McMahan Industrial Services, we know that exposure to extreme weather conditions, such as strong winds, lightning strikes, and hail, can lead to blade fatigue, causing micro-cracks and weakening the blades' structure.

Additionally, the constant rotation and oscillation of the blades can cause stress and strain, further exacerbating the issue.

That's why regular maintenance and repair are essential to guarantee the blades' peak performance and extend their lifespan. Our team uses aerial welding, a specialized technique, to repair damaged blades, restoring their structural integrity and preventing costly replacements.

Cracks in Leading Edges

One of the biggest problems with wind turbine blades is cracks and damage on the leading edge. This area is super vulnerable to erosion and cracking because it's constantly exposed to harsh weather and hit by debris in the air.

The leading edge is really important, and even tiny cracks can cause big problems and compromise the entire blade's structure. To fix this, McMahan Industrial Services has developed advanced materials and coatings to make the leading edge more resistant to erosion and cracking.

They also use special aerial welding techniques to repair cracks and damage, which helps extend the life of the turbine blades. By taking care of cracks on the leading edge, wind turbine operators can minimize downtime, reduce maintenance costs, and make sure they're producing as much energy as possible.

Reduced Downtime With Aerial Welding Experts

Wind turbine operators are constantly looking for ways to minimize downtime and maximize energy production. While aerial welding and advanced materials can help repair cracks and damage, they're not enough to completely eliminate downtime.

That's where McMahan Industrial Services comes in, offering a solution. This approach enables operators to reduce downtime and increase energy production.

Experts inspect turbines, detect anomalies, and even conduct minor repairs - all with minimal human intervention. The result? Faster response times, reduced labor costs, and increased overall efficiency.

McMahan Industrial Services helps wind turbine operators take their maintenance to the next level. By leveraging the power of expert welder, operators can minimize downtime, optimize energy production, and stay ahead of the competition.

Schedule Expert Turbine Repair Teams Now

When it comes to complex repairs and maintenance, wind turbines still need skilled turbine repair teams from McMahan Industrial Services. These experts have the know-how and experience to tackle tricky repairs, ensuring wind turbines run at their best.

Since turbine repair teams often work at heights and with heavy machinery, strong safety protocols are a must. Contact Us Today to meet your welder needs and let us exceed your expectations! Also, browse our project gallery for an idea of projects we undertake or check Google reviews.