For top-quality and safe industrial welding in Iowa City, follow these best practices for inspections. Check visually and use non-destructive tests to spot flaws, protecting weld strength.

Schedule expert inspections promptly to meet standards and avoid costly mistakes. These steps are crucial for project success and worker safety with McMahan Industrial Services.

Welding Inspection Importance

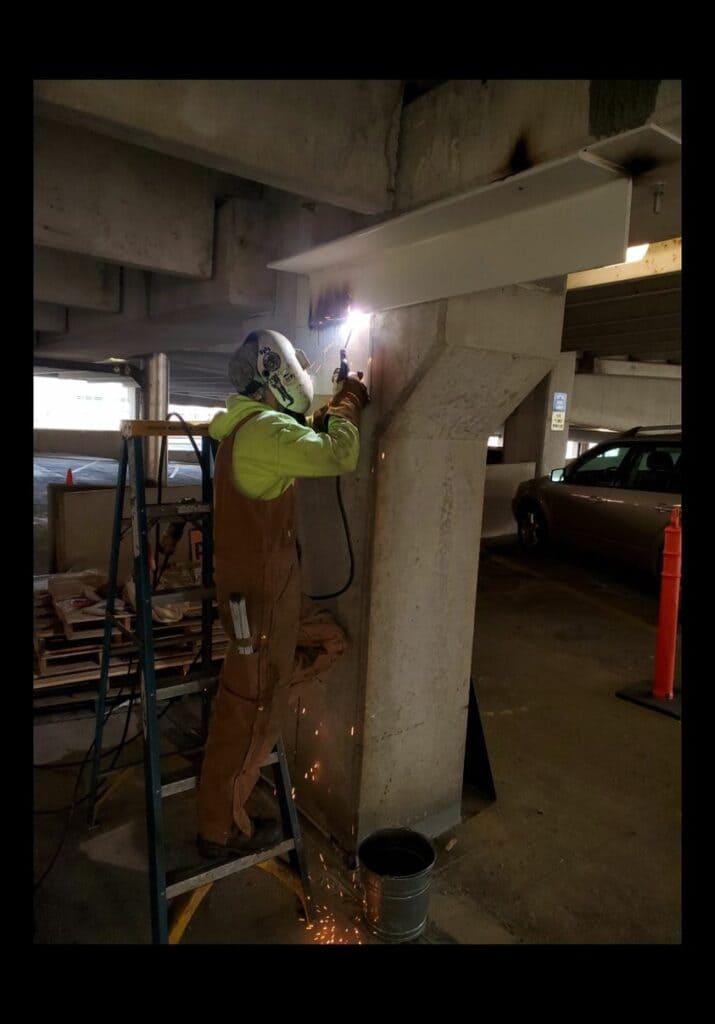

To ensure the quality and safety of industrial welding projects, conducting welding inspections is crucial.

These inspections involve thorough checks to prevent hazards and defects that could compromise weld integrity. By identifying issues early on, we can ensure that welds meet required standards and specifications, upholding project quality and worker safety.

Adhering to safety measures and performing regular inspections are essential for a secure working environment and successful welding outcomes.

At McMahan Industrial Services, safety always comes first!

Welding Inspection Challenges

Inspecting welds in industrial settings can be challenging, requiring close attention to detail and expertise to address potential issues. While visual inspection is important, it may not always uncover internal defects. Non-destructive testing (NDT) methods like ultrasonic testing or radiography are crucial for detecting hidden flaws.

Challenges can arise from the complexity of weld shapes, different material thicknesses, and the need for specialized equipment. Ensuring proper lighting and access to all areas of the weld can also be tricky. Interpreting NDT results accurately demands well-trained personnel.

To tackle these challenges effectively, a comprehensive approach that combines visual inspection with advanced NDT techniques is essential to guarantee the integrity and safety of welded components at McMahan Industrial Services.

Welding Inspection Techniques

For thorough weld inspection, McMahan Industrial Services suggests combining visual checks with non-destructive testing methods. Visual inspection means examining welds for surface flaws like cracks, porosity, or incomplete fusion. Make sure the bead size and shape are consistent without any visible defects.

Non-destructive testing, such as ultrasonic or radiographic methods, can detect hidden flaws inside the weld without causing damage. This detailed analysis helps identify issues that could weaken the weld.

Schedule Expert Welding Inspections Now!

Ensure the quality and safety of your welds by booking professional welding inspections promptly with McMahan Industrial Services. Expert opinions and welding certification are crucial for meeting industry standards.

By scheduling inspections with certified professionals, you can get valuable feedback on your welds' quality. These experts can spot potential issues early on, helping you avoid costly mistakes and maintain the structural integrity of your welds.

Don't delay – take proactive steps to schedule expert welding inspections now to uphold safety and quality in your projects. Your commitment to thorough inspections will pay off in the long run by minimizing risks and ensuring compliance with regulations. Contact Us Today to meet your welder needs and let us exceed your expectations! Also, browse our project gallery for an idea of projects we undertake or check Google reviews.