Keep your hydraulic system in top shape in Kansas City, MO with regular maintenance from McMahan Industrial Services. It's crucial to check it regularly, fix any leaks, and keep an eye on fluid levels.

Our skilled millwright services focus on preventive maintenance to catch issues early on and avoid costly repairs. Our expert technicians conduct routine inspections and servicing to extend the system's lifespan and improve its efficiency.

Safety is key, so always wear protective gear and be alert for any changes in performance. By following these steps, you can maintain your hydraulic system effectively and prevent unexpected breakdowns.

Hydraulic System Maintenance Importance

Regular maintenance of hydraulic systems is crucial for optimal performance and durability. Preventative upkeep is key to keeping your hydraulic system running smoothly.

By conducting routine checks, analyzing fluid quality, and inspecting components, you can catch potential problems early and maintain system efficiency. Simple tasks like fixing leaks, changing filters on time, and monitoring fluid levels can make a big difference in the overall health of your hydraulic system.

Neglecting these tasks can result in reduced performance, expensive repairs, and safety risks. Remember, a well-maintained hydraulic system not only works better but also lowers the chances of unexpected breakdowns that could jeopardize workplace safety.

Trust McMahan Industrial Services to help you keep your hydraulic system in top shape.

Hydraulic System Troubleshooting Techniques

When troubleshooting hydraulic system problems, start by checking for odd sounds, leaks, or performance changes during regular maintenance. Use diagnostic tools to find the main issue. Look for loose connections, damaged hoses, or faulty seals that could be causing problems.

Make sure all parts are well lubricated and fluid levels are correct. Use tips like checking for air, monitoring pressure, and inspecting filters. Always prioritize safety and wear protective gear. Stay alert and proactive to keep your hydraulic systems efficient and reliable.

Hydraulic System Flushing Benefits

Regularly flushing your hydraulic system is essential for optimal performance and longevity. By getting rid of contaminants like dirt, debris, and sludge, flushing ensures that your hydraulic system runs smoothly.

This process boosts efficiency because clean fluid allows components to work at their best without unnecessary friction or wear. Moreover, flushing helps prevent damage caused by contaminated fluid circulating through the system, thus extending the life of your equipment.

Keeping your hydraulic system clean through regular flushing not only improves machinery performance but also guards against potential breakdowns resulting from neglected maintenance. Prioritize this simple task to preserve the efficiency and durability of your hydraulic equipment with McMahan Industrial Services.

Schedule Expert Millwright Services

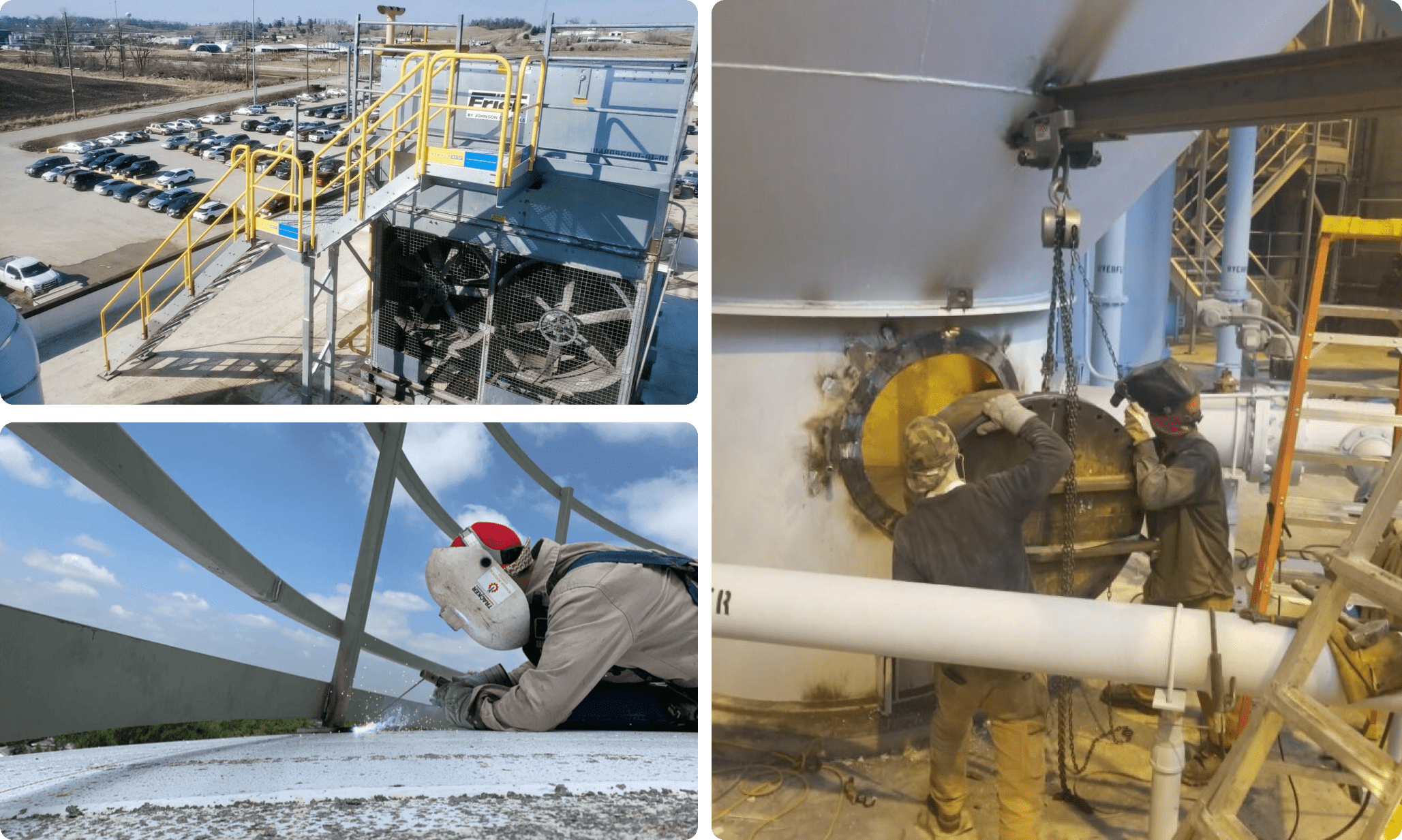

When it comes to maintaining your hydraulic system, scheduling expert millwright services is essential. Trusting McMahan Industrial Services for expert guidance ensures that your hydraulic system receives the necessary preventive maintenance to operate safely and efficiently.

Our skilled millwrights will conduct regular inspections and servicing to spot any potential issues before they become costly failures. With their expertise, they can identify early signs of wear or malfunction and make timely adjustments or repairs to keep your system in top shape.

Contact Us Today to meet your welder needs and let us exceed your expectations! Also, browse our project gallery for an idea of projects we undertake or check Google reviews.