In Iowa City, IA, metal fabrication is super important for building and maintaining renewable energy projects. Custom metal solutions are key to making sure solar and wind energy systems are strong and reliable.

At McMahan Industrial Services, we use precision metal fabrication for energy storage solutions like battery enclosures. Our laser cutting technology helps improve designs while reducing waste.

Expert welding techniques are crucial for putting together complex metal parts in wind turbines. This helps cut down on defects and makes everything safer.

By focusing on strength, choosing the right materials, and carefully calculating loads, McMahan Industrial Services ensures that our metal fabrication services meet safety standards and regulations.

If you want to know more about these solutions, we're here to help!

Renewable Energy Metal Solutions

Renewable energy projects, like wind farms and solar panel installations, depend a lot on custom metal fabrication for the structural components that support clean energy generation.

-

It's super important to ensure these structures are safe and reliable to prevent accidents and keep energy flowing continuously.

-

Plus, energy storage solutions like battery enclosures need precise metal fabrication to ensure safe and efficient operation.

-

By focusing on safety and precision in metal fabrication, renewable energy projects can lower risks and boost energy output, helping to create a sustainable future.

-

When project developers choose a trustworthy metal fabrication service like McMahan Industrial Services, they can be sure they're meeting safety standards and regulations.

Wind Turbine Structural Issues

The structural integrity of wind turbines is really important in the renewable energy industry. Even small problems can lead to big losses in power output and can be dangerous for nearby communities.

-

To avoid these risks, turbine designs need to focus on being strong and reliable. This means carefully choosing materials, calculating loads, and analyzing stress. A well-designed turbine can handle different weather conditions, including extreme storms and vibrations that can wear them down over time.

-

Regular inspections and maintenance are also key to spotting and fixing potential structural issues before they turn into major problems. By focusing on structural integrity, wind turbine operators can ensure safe and dependable energy production, which helps protect the environment and local communities.

Companies like McMahan Industrial Services play an important role in making sure turbines are built and maintained properly to achieve these goals.

Laser Cutting for Efficiency

To keep wind turbines strong and also make them better in design and function, companies like McMahan Industrial Services are using advanced metal fabrication techniques, such as laser cutting. This method helps improve efficiency and precision during production.

Laser cutting makes precise cuts and reduces waste, ensuring that the final product meets strict specifications. This is especially important when working with tough materials like high-strength steel and aluminum alloys, which are often used in building wind turbines.

Expert Welding for Turbines

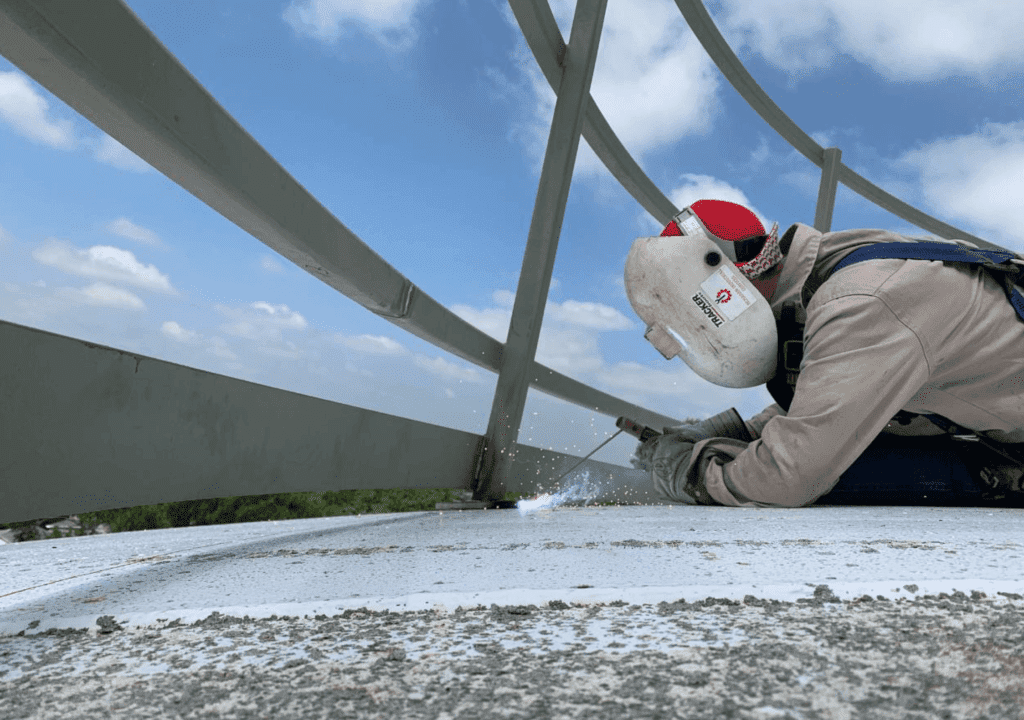

At McMahan Industrial Services, our expert welders have completed over 100,000 welding hours, using specialized techniques and tools to join complex metal parts. This helps us create strong and durable wind turbine structures that can handle tough weather conditions.

We customize our welding methods to fit the specific needs of turbine maintenance, ensuring that every weld is top-notch in quality and reliability. By using advanced welding techniques, we reduce the chances of defects and make sure that turbines run smoothly and safely.

Contact Us Today to meet your welder needs and let us exceed your expectations! Also, browse our project gallery for an idea of projects we undertake or check Google reviews.