Are you ready for the world of pipe welding in Omaha, NE? In this discussion, we will explore the potential dangers of fumes in welding safety. From understanding the importance of proper ventilation to using personal protective equipment, we will equip you with the knowledge you need to safely navigate the world of pipe welding.

So, wear your helmet and tighten your gloves because the McMahan Industrial Services journey to welding safety starts now.

How to Weld Pipe?

When welding pipe, following a precise and technical process is crucial while prioritizing safety measures throughout the operation. Ensuring welding safety is essential to protect yourself from hazards and achieve a successful pipe welding job.

-

Before you begin, ensure you have the appropriate personal protective equipment (PPE), such as welding gloves, helmets, and fire-resistant clothing.

-

Thoroughly clean the area where you'll be welding to eliminate any flammable materials. Then, secure the pipe in position using clamps or a vise.

-

Preparing the joint is a critical step, which may involve beveling the pipe ends and cleaning them with a wire brush. Afterward, apply the suitable welding technique, such as TIG, MIG, or Stick welding, following the recommended settings for the pipe material and thickness.

-

Once the weld is completed, visually inspect it and perform non-destructive testing if required. Finally, ensure proper ventilation to minimize exposure to welding fumes.

By following these steps and prioritizing welding safety, you can achieve a high-quality pipe weld and minimize potential hazards.

At McMahan Industrial Services, we prioritize safety and quality in all our welding operations.

What is the Best Pipe Welding Method?

The best pipe welding method depends on various factors, including the materials, the specific application, and the desired weld quality. Several methods are commonly used in pipe welding, each with advantages and considerations.

-

Shielded metal arc welding (SMAW) or stick welding is a popular method. SMAW is versatile and can be used on various materials, making it suitable for different applications.

-

Another method is gas metal arc welding (GMAW), or MIG welding, which utilizes a continuous wire electrode and shielding gas. This method provides a high deposition rate, making it efficient for large-scale projects.

-

Tungsten inert gas (TIG) welding is another commonly used method for pipe welding, offering precise control and producing high-quality welds.

Regardless of the method chosen, it's essential to prioritize safety and minimize fume hazards by implementing proper ventilation and using appropriate personal protective equipment.

Pipe Welding Safety Tips

When it comes to ensuring the safety of pipe welding operations, following proper protocols and implementing effective safety measures is crucial. To protect yourself from potential hazards, it's essential to be aware of welding fumes safety and follow these pipe welding safety tips.

-

First, always work in a well-ventilated area to minimize exposure to welding fumes. If ventilation is insufficient, use respiratory protection such as a powered air-purifying respirator (PAPR) or a half-face respirator with particulate filters.

-

Additionally, wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and flame-resistant clothing to protect against burns and injuries.

-

Before starting any welding task, inspect your equipment and ensure it's in good working condition.

-

Finally, be mindful of your surroundings and maintain a clean work area to prevent trips, falls, and accidents.

Get a Free Quote on Pipe Welding Services

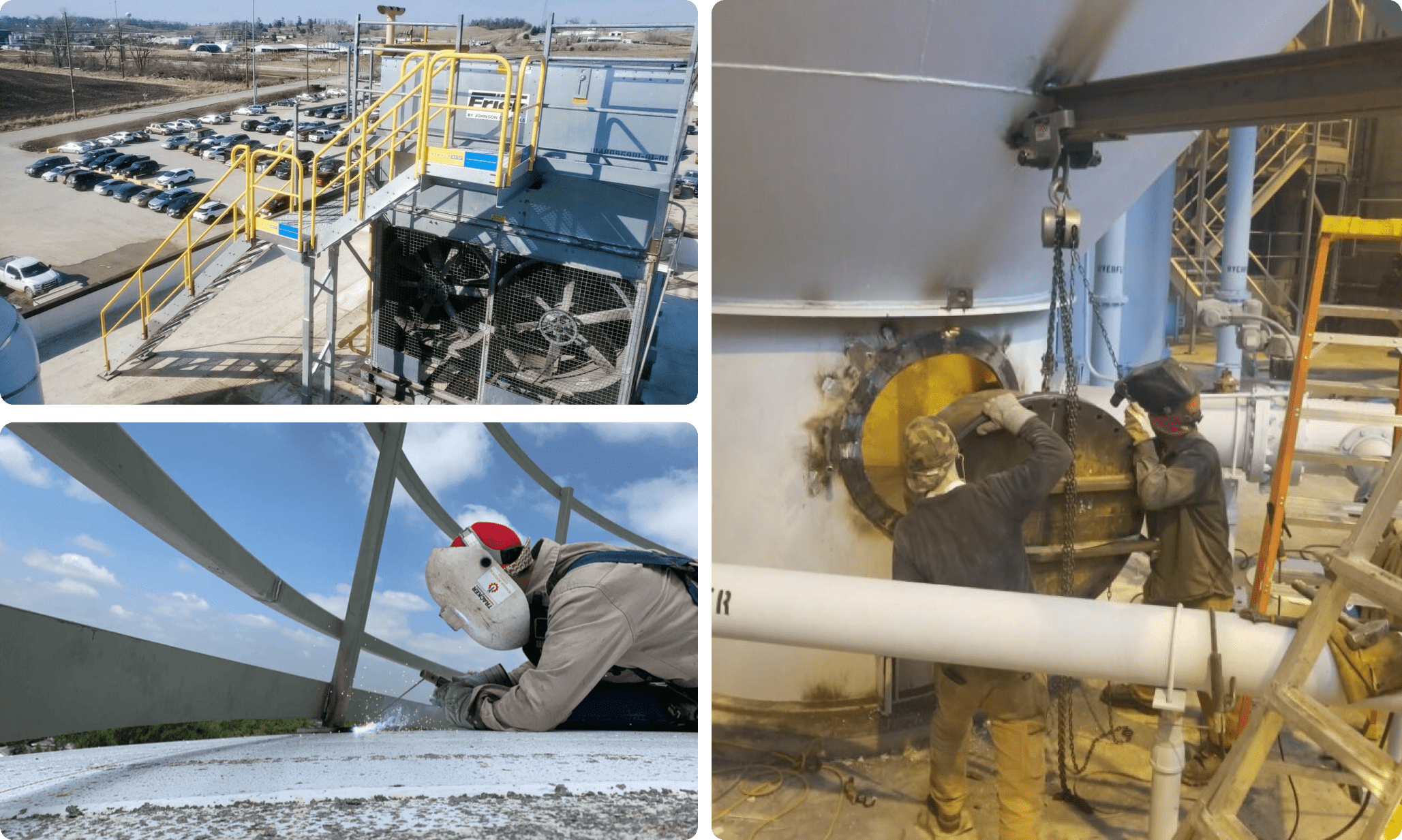

McMahan Industrial Services offers professional pipe welding services in Omaha, NE, tailored to meet specific requirements.

We also provide mobile welding services, ensuring convenience and immediate professional service even in remote locations. Contact Us Today to meet your welder needs and let us exceed your expectations! Also, browse our project gallery for an idea of projects we undertake or check Google reviews.