Portable welding equipment is really important for construction sites in Omaha, NE. It helps workers do their jobs safely and efficiently, even in hard-to-reach areas.

McMahan Industrial Services can create customized mobile workshops that fit your specific needs, making sure all the necessary tools and equipment are easy to access. By investing in portable welding solutions, you can cut down on downtime and boost productivity.

Plus, better safety standards can save you money and make your customers happier.

So, learn how McMahan Industrial Services can help you optimize your construction site's portable welder operations!

Portable Welder on the Go

Mobility is really important in many industries, and welding is no different. Welders often need the flexibility to work on-site or in remote places where regular welding equipment just won't work.

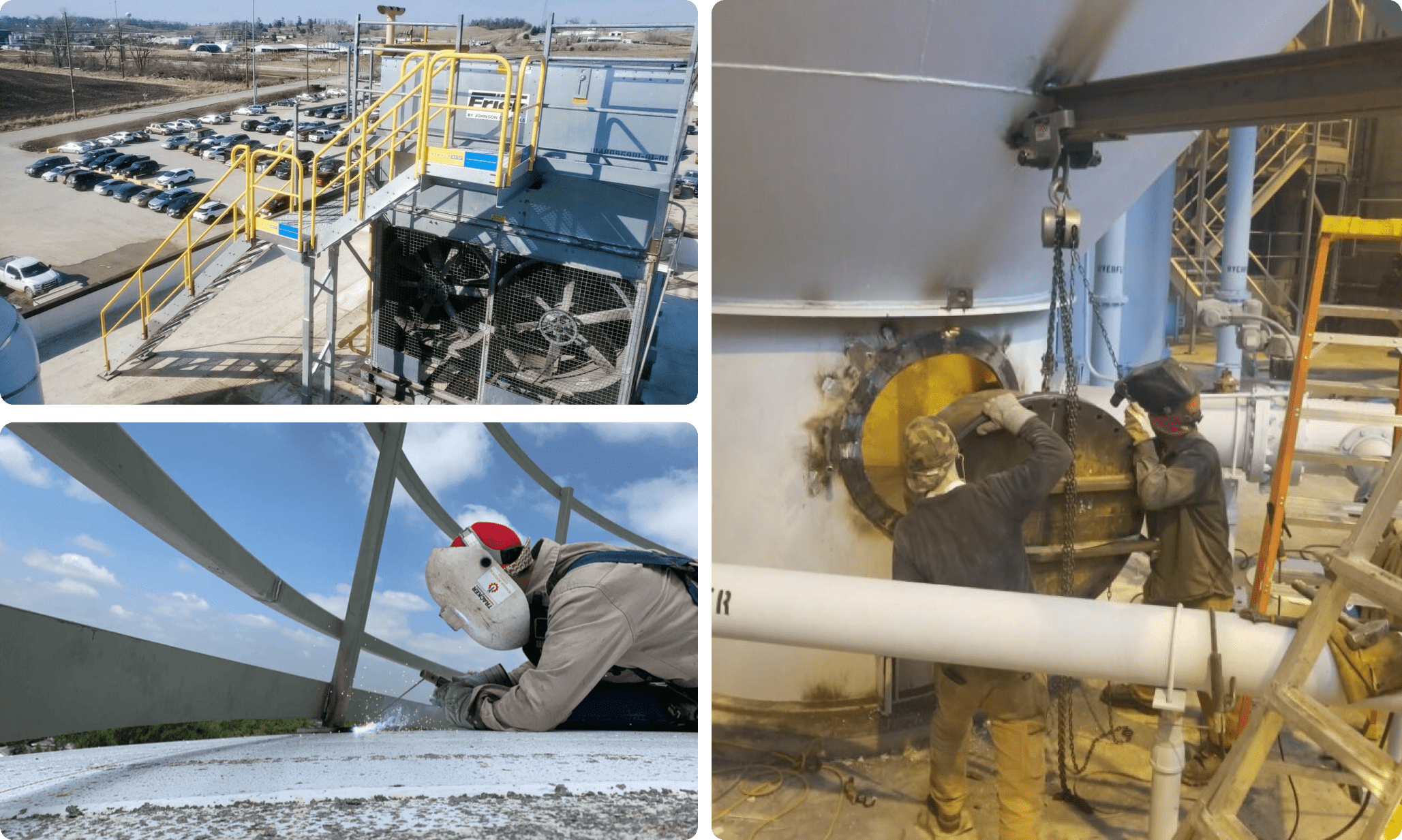

That's where McMahan Industrial Services comes in with their mobile workshops and field repair services, which can be a real game-changer.

With portable welding equipment, technicians can safely and efficiently make repairs and do maintenance tasks, even in tough-to-reach areas. We customize our mobile workshops to meet specific needs, making sure all the necessary tools and equipment are easily available.

By investing in these portable welding solutions, businesses can cut down on downtime, boost productivity, and improve safety standards.

Equipment Transportation Challenges

Transporting heavy welding equipment to remote job sites can be challenging. It requires careful planning and the right vehicles to ensure that everything is delivered safely and efficiently.

At McMahan Industrial Services, we know that keeping equipment secure during transportation is crucial to prevent damage, theft, or loss.

-

You can do this by using protective covers, securing the equipment to the vehicle, and creating a plan for site logistics—like designating specific storage areas for equipment.

-

It's also important to check the site conditions and plan the transportation route to avoid any potential damage.

-

By focusing on equipment security and site logistics, construction teams can cut down on downtime, boost productivity, and keep the work environment safe.

-

With effective planning and coordination, we can tackle equipment transportation challenges, allowing welding professionals to concentrate on getting the job done.

Efficient Arc Stability Control

Achieving efficient arc stability control is really important for creating high-quality welds. It helps welding professionals keep a consistent arc length and voltage, which leads to stronger and more durable joints.

This is especially crucial on construction sites, where safety is key.

-

At McMahan Industrial Services, we understand that arc monitoring plays a vital role in maintaining arc stability.

-

It allows welders to adjust their technique in real-time, preventing defects and ensuring the best possible weld quality.

-

Effective power management is also essential, as it helps welders control the flow of energy and keep the arc steady.

-

By combining these two elements, welders can achieve efficient arc stability control, leading to safer and more reliable welds.

-

This not only reduces the risk of accidents but also ensures that construction projects are completed on time and to a high standard.

Schedule On-Site Portable Welder Now

Construction companies understand the importance of stable welding processes. That's why many are choosing to schedule on-site welding services that fit their project needs and timelines.

To make the most of their labor, it's crucial to work with skilled welding professionals who can adjust to any changes in the project.

Contact Us Today to meet your welder needs and let us exceed your expectations! Also, browse our project gallery for an idea of projects we undertake or check Google reviews.